Why You Should Leverage Predictive Analytics for Supply Chain Decision-Making

Your shipping network generates a wealth of data that can be used to de-risk process decisions. Most organizations are already making use of detailed reporting and analytics to understand historical performance and costs — but in the age of predictive analytics, that’s not enough to keep operations on par with more technologically advanced competitors.

By centralizing shipping data and running it through proprietary machine learning models, modern tools — like Shipium Simulation — can help you go a step further by understanding what’s likely to happen, not just what has happened.

In this article, we’ll review the benefit of using predictive analytics for supply chain optimization, explore network simulation use cases that forward-thinking organizations (and some Shipium customers) are focused on, and break down the business impact of each.

What are supply chain predictive analytics?

Supply chain predictive analytics uses data analysis techniques, like probabilistic modeling and machine learning, to forecast future trends and outcomes within a supply chain, allowing businesses to proactively prepare for potential disruptions and optimize their operations by predicting future outcomes. Since supply chains are highly volatile in nature, most future decisions and outcomes are stochastic, and benefit from predictive analytics focused on probabilities.

Data analysis powers to make better supply chain predictions

Before getting into specific initiatives, it’s worth noting that simulation use cases broadly fall into one of two buckets — optimizing current processes in an effort to capture more savings and moderately improve efficiency, and planning future initiatives that represent larger-scale transformations to the business.

Using simulation to optimize supply chain operations

While predictive analytics software can help you reimagine supply chain operations in comprehensive ways, it’s just as important to make sure that your current processes are creating as much value as possible. Performing a large-scale overhaul of key shipping processes may not always be realistic, but there’s almost always room around the margins for improvement.

Some examples of use cases include:

Base rate optimization

When it comes to process optimization, a great way to create value is to ensure that you’re paying carriers the minimum amount required to still deliver on expectations based on customer demand. Enterprises are usually paying more than they need to be here. Fortunately, simulation can help you address that.

By running simulations on historical shipments and applying constraints like desired delivery dates and maximum spend threshold, you can receive machine learning predictive analytics on which carriers and service options are most likely to meet your defined criteria. This can power changes like intelligent downgrades, which involves moving volume to economy shipping options that will still meet required delivery dates.

Shipium also automates zip-zone mappings, allowing for more precise calculation of shipping distances and the ability to dynamically account for factors like fuel prices, weather patterns, and demand.

Accessorial avoidance

With the right technology, there’s no reason an organization should incur excessive accessorial charges, which are largely the result of limited supply chain visibility and poor planning.

You can address this by running a simulation to accurately predict the impact of surcharge and accessorial changes to your network — for example, simulating the impact of increased Dimweight fees to determine if it’s worth moving volume to a different carrier or service option.

You can also simulate the impact of specific efficiency improvements on the overall bottom line. An example of this would be measuring the impact of enhanced packaging efficiency to determine if it’s an area that warrants improvement.

Transit optimization

Date constraint-based optimization enables you to run simulations on historical shipments to see which carriers can support specific timelines.

You can also run a parcel spend optimization scenario that’s focused on identifying the greatest savings possible, regardless of date constraints. If you’re like most organizations, you’ll likely set up your own custom criteria based on your customers’ expectations and larger business priorities — weighing both cost and performance implications in every analysis.

In either case, you can make transit decisions based on a detailed understanding of true performance and cost.

How simulation enhances planning for operational changes

As we mentioned earlier, simulations focused on planning for the future involve using predictive analytics for supply chain refinement, weighing larger-scale changes to your network, market conditions, and shipping operations that transform the way you’re currently doing business.

When it comes to forecasting demand and making such large-scale changes, it’s always worth considering working with strategic consultants who have experience managing such projects. At Shipium, we work closely with these types of partners to jointly ensure faster shipping, cost reduction, and greater process efficiency, and recommend our strategic partner Green Mountain as the best place to start.

For enterprise retailers who choose to work with firms in addition to investing in Shipium, the process is straightforward — the consulting partner helps to develop a tailored shipping strategy, the retailer then automates execution of that strategy with Shipium, and both perform continuous monitoring of the overall shipping network.

Here are some good places to start when it comes to specific forward-looking use cases for supply chain predictive analytics solutions:

Carrier expansion

First, whether you’re currently single-threaded or not, adding additional carriers can be a great way to expand service capabilities, gain negotiating leverage (more on this shortly), and cut costs. Unfortunately, it’s not always easy to determine which carriers or services will best help to meet your goals, especially given that each one prices and communicates value differently.

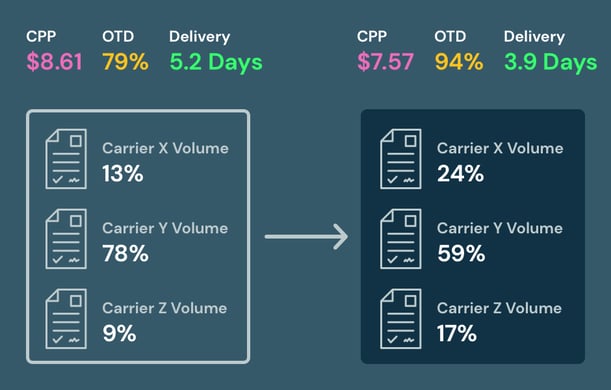

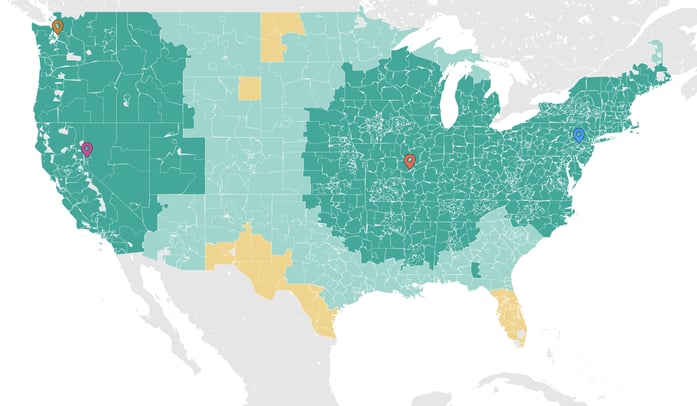

By simulating historical shipments with new carriers (Shipium’s Carrier Network covers >99% of the U.S.), you can quickly determine how volumes would shift to optimize costs, as well as how performance would be impacted. This enables you to make more informed decisions about which carrier(s) to add, including choosing from regional options, not just the big four.

Rate renegotiation

When you go into negotiations with carriers not knowing how changes to discount tiers, surcharges, and service options will impact performance and costs, you’re giving them the upper hand at the table.

By running simulations that account for these types of changes, you can enter into negotiations armed with the knowledge of exactly which contract terms will best benefit your future network performance.

Network expansion

Given the amount of time and money that must be invested to expand your carrier network by adding nodes and/or services, it’s worth knowing the expected impact of those changes before committing to such an investment. Running simulations on historical shipments while changing network parameters can help you understand just how those changes will impact operations.

For example, if you’re considering adding a new warehouse to improve shipping process workflow speed in a specific geography, you can run simulations to determine the best place for that warehouse based on carrier performance and demand. Similarly, you can simulate whether shipping directly from stores offers a better alternative.

If you feel unable to keep up with growing demand and are considering working with a 3PL partner to scale shipping operations, you can test how working with that partner would impact performance and costs.

Enhance supply chain decision-making with Shipium

Today’s leading operations and analytics teams are moving beyond reporting on historical performance — they’re using the wealth of data that’s generated within their networks to make predictions that inform key process decisions. These predictions can be focused on ways to cut costs and improve current processes, or be more future-oriented and provide insight on how to overhaul existing processes.

In either case, it’s important for organizations who want to optimize their processes to find ways to better leverage their data and generate useful forward-looking insights from it.

Book a demo today and explore how Shipium can help you leverage predictive analytics for supply chain decision-making.

Frequently Asked Questions

Can predictive analytics in supply chain planning help me reduce shipping costs?

Yes. Predictive analytics will show areas of efficiency by changing the trade offs you need to make that impact costs. For example, if you are guaranteeing 2-day delivery to customers to gain a competitive edge and thus having to use expensive 2-day shipping service methods, you can use predictive analytics to see some percentage that could shift to slower shipping methods yet still hit a 2-day window to meet customer demand, thus saving on costs.

How long does it take Shipium Simulation to calculate the impact of operational changes?

Shipium’s predictive modeling helps give an immediate perspective on where to cut costs. Implementing predictive analytics with a simulation technology is straight forward: identify a hypothesis, load data into the tool, make tweaks related to the hypothesis, and see the results.

Can Shipium generate supply chain predictive analytics using data from my legacy platform?

Yes. A measure of good predictive analytics tools is the ability to take existing data from a legacy system, merge it with other datasets, and see the results from a simulation. Shipium’s platform helps you leverage your existing data in new ways through an easy interface.

Anurag leads Shipium’s product marketing efforts, focused on helping the world understand how our platform adds incredible value for everyone.